To what extent are sealing machines important in the packaging industry and scopes it has in food and beverage, pharmaceutical and consumer industries. The function of these products is to effectively and securely close the cans so that the contents of the cans do not deteriorate or get spoiled or get contaminated within the shelf life of the product. It would be pertinent to mention here that there can be nothing more crucial than ensuring that the product safety and product integrity is not compromised in any way for the simple reason that customers use products based on their trust and this trust is built over the brand with which they identify themselves with. In this article we will discuss how sealing machines can increase the level of product safety and integrity, and how this is backed up by the high quality components from valve manufacturers. We will also elaborate how suppliers of industrial valves enhance the reliability of these machines.

Contents

Safety and Security

Among the many roles of can sealing machines it is expected of them to offer hermetic sealing in order to protect the contents of the can from outside interference. In the case of a perishable product such as food or a pharmaceutical product, it is imperative that an airtight seal is attained so that the product does not deteriorate, get ruined by moisture or heat, or gets contaminated with other substances. The seal helps in maintaining the hygiene of the product to be consumed and also maintaining the quality of the product until the time it is supposed to expire.

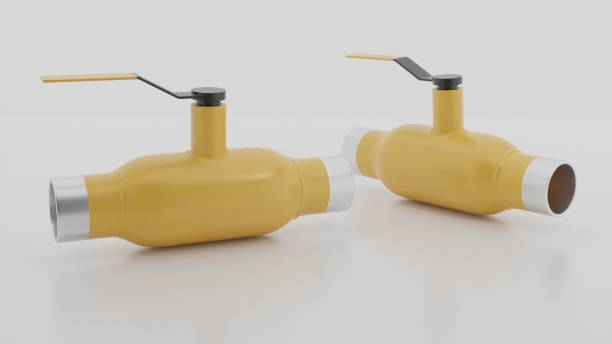

In order to establish the level of sealing precision required for usage in can sealing machines, such machines are fitted with technologies for ideal sealing. Valves used in these machines must be of high quality since they are used in controlling the flow of air and other gasses during the sealing process. Valve manufacturers specialize in supplying these parts that control such flows and guarantee that the sealing processes are effective and smooth. Many manufacturers have to ensure that they create the right pressure in order to fully seal a valve in the manufacturing process, and high quality valves mean that they do not have to worry about this.

Contamination Control and Shelf Life

Food and drug packaging industries are some of the most dangerous areas of contamination of packaging products. The nature of the lid of a can lends to its inability to provide a perfect seal, a small space could be left open and this result in entrance of bacterias, mold, or other contaminants were channeled into the can thereby posing a great risk to the product. Can sealing machines are particularly developed in a way that reduces this risk as much as possible, whereby can sealing is done perfectly such that there are no loose areas that terrorists may exploit to place their contaminants.

The position that industrial valve suppliers take in this process is very central. These suppliers offer valves which can be used in high speed can sealing machines due to their tough operational conditions. The valves themselves have to function perfectly, while providing the right amount of pressure and flow that will enable each can to be sealed properly. When used in conjunction with the latest in sealing techniques, these valves assist in retaining product quality in the longer term, through the minimisation of degradation due to contaminants and in maintaining the freshness of the product within the packaging.

Production Endowments and Flexibility

So, apart from increasing product safety and quality, can sealing machines are required for improving productivity. High speed can sealing machines can seal up to a thousand cans in one hour and thus are useful where large production is taking place. These sealing processes have to be consistent and highly reliable for the production processes to run at their optimum levels and for there not to be a lot of time consumed in sealing.

Valve manufacturers bear a great responsibility of making sure that sealing machines function to their optimal capabilities. Such valves have to be rather robust, faithfully serving and designed for handling machines that function in a continuous mode. Through provision of quality valves, industrial valve suppliers assist in the ability of firms to seal their machinery effectively thus enhancing reduced chances of equipment breakdown and consequently enhancing the ability of the production lines to run without interruption.

Various foods call for various types of seals given aspects like the contents of the can, the kind of can to be used amongst others general aspects such flammable products should have flame retardant sealing. Sealing machines must be flexible in that they need to be capable of sealing a carbonated beverage or a canned vegetable or even a pharmaceutical product. This is made possible by the flexibility of the machines; one is able to design the particular machine according to the need of a particular product.

Very often valve manufacturers supply the individual components that make such an adjustment possible. They allow manufacturers to select a variety of valve types that come with varying features and characteristics, thus making it possible for them to design and build can sealing machines that will suit the extent of their production lines. Manufacturers of industrial valves make sure that these kinds of valves are widely available and can be easily used in equipment thereby affording the process the advantage of flexibility.

Sustainability and Waste Management

Sustainability as a factor in the packaging industry is gradually arising as a major factor for concern. Does sealing machines have the potential of supporting sustainability initiatives by minimizing wastages whilst sealing products effectively with the least quantity of the material. Reducing the amount of rework and rejects helps to also minimize the amount of waste that there is, thus making the most out of resources.

Essential features and measures affected by the valve manufacturers and the industrial valve suppliers are also aligned to these sustainability goals. Through product design they contribute by offering valves that are effective and have a lower effect on the environment as concerning the packaging process. Premium valves help ensure that sealing machines can deliver their function efficiently, with the most minimal energy consumption and wastage of materials.

Conclusion

This paper seeks to examine the role that sealing machines play in making an improvement to product safety, product integrity and efficiency in the packaging vertical. The reliability of these machines depends on the quality of some of the items used in the machines, especially the valves used in sealing. The suppliers of valves and industrial valves also supply you with the crucial components that help make sealing machines precise and effective and that indirectly makes the packed products safe and top quality. This relationship between the can sealing machine manufacturers and valve suppliers will remain as essential as ever, in the progressing efforts to find better ways of packaging increasingly required by the market for highest safety and ecological standards.